Specs at a glance

-

Process temperature

PA pressure cylinder (manually only):

Max. 80 °C (176 °F)

Stainless steel pressure cylinder:

up to 100°C (212 °F) with continuous operation up to 6 bar (87 psi) -

Process pressure

PA pressure cylinder: Max. 6 bar (87 psi)

Stainless steel pressure cylinder: Max. 10 bar (145 psi)

Pneumatic outlet safety seal:

6 bar at 100 °C (87 psi at 212 °F)

Field of application

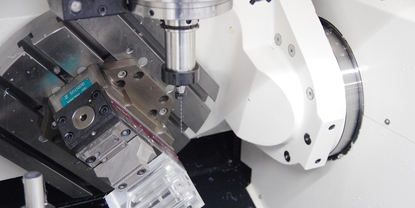

The Cleanfit CPA473 retractable assembly is designed for application in fibrous or sticky media. Its patented sleeve seals and integrated scrapers make sure that nothing sticks to the sensor. Cleanfit offers highest operating comfort: You can replace sensors and even service the assembly while the process is running. The optional electric or pneumatic control system enables automated cleaning and calibration even in difficult processes.

Cleanfit CPA473 is intended for use in tanks and pipes in:

Chemical industry

Paper industry

Wastewater / industrial water

Power plants

Refuse incinerators

It is suitable to be used with pressures of up to 10 bar (stainless steel cylinder) or 6 bar (PA cylinder).

Benefits

Safe and reliable separation from the process by ball valve, even under harsh conditions

No process interruption for electrode cleaning and calibration – saves maintenance time and costs

Extended operating life of electrodes due to automatic cleaning

Suitable for application in sticky and fibrous media thanks to integrated scraper and sleeve seals

Flexible adaptation to all applications by great variety of materials and process connections

Predecessor

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

-

-

Technical Information (TI)

Technical Information Retractable assembly Cleanfit P CPA473

Retractable stainless steel process assembly with ball valve, for pH and

ORP electrodesEN 01/11/200901/02/200501/09/200301/10/2002Language:

English

Version:

01/11/2009

File size:

961.3 KB

File name:

TI344CEN_1109.pdf

-

-

-

Technical Information (TI)

Technical Information Topcal S CPC310

Fully automatic measuring, cleaning and calibration system in hazardous

and non-hazardous areasEN 22/07/201501/07/2006Language:

English

Version:

22/07/2015

File size:

2 MB

File name:

TI00404CEN_1315.pdf

-

-

-

Operating Instruction (BA)

Operating Instructions Cleanfit P CPA473

Retractable SS process assembly with ball valve for pH and redox

sensorsEN 01/11/200901/05/200501/02/200501/01/200401/08/2003Language:

English

Version:

01/11/2009

File size:

2 MB

File name:

Ba344cen_1109.pdf

-

-

-

Installation Instructions (EA)

EA for Cleanfit CPA473

Service Manual for Retractable process assembly Cleanfit CPA473

EN 20/02/2025Language:

English

Version:

20/02/2025

File size:

2.8 MB

File name:

71217189_Service_CPA473.pdf

-

-

-

Installation Instructions (EA)

EA Spare parts kits for Cleanfit CPA473 process retractable assemblies

Seals, in contact with medium

EN 24/02/2025Language:

English

Version:

24/02/2025

File size:

1.7 MB

File name:

EA01535CEN_0125-00.pdf

-

-

-

Installation Instructions (EA)

EA Spare parts kits for Cleanfit CPA472D, CPA473 and CPA474 process retractable assemblies

Seals, not in contact with medium

EN 19/02/2025Language:

English

Version:

19/02/2025

File size:

934.3 KB

File name:

EA01523CEN_0125-00.pdf

-

-

-

Special Documentation (SD)

SD CleanFit Servicekits / Spare part kits

CleanFit Wechselarmaturen / Retractable assemblies

EN 01/07/2003Language:

English

Version:

01/07/2003

File size:

1.6 MB

File name:

Sd096ca2.pdf

-

-

-

Competence Brochure (CP)

pH measurement in industrial processes

Selection and engineering guide for different industries and

applicationsLanguage:

English

Version:

02/12/2021

File size:

3.2 MB

File name:

CP00010CEN_1621_pH selection guide_2021.pdf

-

-

-

Competence Brochure (CP)

産業プロセスにおけるpH測定

さまざまな産業およびアプリケーション向けのpH測定セレクションガイド

Language:

Japanese

Version:

08/02/2024

File size:

2.6 MB

File name:

CP00010CJA_1315_1024_pH_selection_guide.pdf

-

-

-

Competence Brochure (CP)

pH-Messung in Industrieprozessen

Auswahl- und Engineering-Hilfe für verschiedene Industriebranchen und

ApplikationenLanguage:

German

Version:

01/12/2021

File size:

3.3 MB

File name:

CP00010CDE_1621_pH Auswahlhilfe_2021.pdf

-

.jpg)